information

Glassfiber Reinforced Concrete

What is GRC?

GRC is indeed one of the most versatile and flexible building materials available to architects and designers. It is not a singular material but a family of high performing composites made-up of cement, fine aggregates, water, admixtures, and alkali resistant glassfibres.

Cement mortars carry high compressive strength properties whereas glassfibre is flexible, imparting increased impact, flexural and tensile strengths. When the two materials are mixed, the outcome is a super composite that provides a world of possibilities.

This composite can be engineered to adapt to a wide range of applications. GRC products can be formed into sections as thin as 6mm, so they weigh, far lighter than traditional precast concrete products.

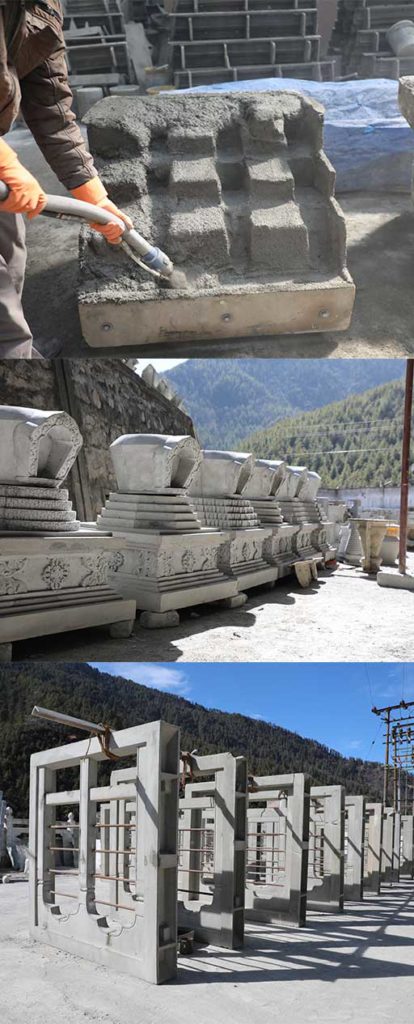

Bhutan GRC is the primary manufacturer of GRC (Glassfibre Reinforced Concrete) in Bhutan. Our products are made of reinforced concrete with Alkali Resistant Glassfibres, ideal for the construction of lightweight architectural façades. Due to the material’s unique flexibility, ductility and lightness, GRC enables amazing architectural designs. In a word, it is revolutionary.

The possibilities that can be achieved with GRC when it comes to shapes and sizes are unlimited. Bhutan GRC has helped define some of the most ornate and decorative buildings in the Kingdom of Bhutan, such as the Golden Throne (Sengthri) cladding panels for the Largest Guru Padmashambava Statue (154.0 ft tall) in Takila, Eastern Bhutan.

Why GRC?

Saving in consumption of Sand , water , steel & cement :

Conserves natural resources and has minimal usage of cement and steel, there by reducing multiple inventories and requirement of space at site .

Prefab and better quality product:

Being factory made ensures consistency in quality of panel while supplied and used . Hence durability of the building is enhanced.

Resistant to Earthquakes & Fire:

GRC panels exhibits superior ductile properties and also permits the designer to reduce the mass of the structure, limiting the impact of accelerations caused during seismic disturbances. The fire resistance nature of the GRC panel is an advantage against conventional walling material .

Time:

Time saving potential in GRC based system is more than 50% than any other conventional system because requirement of plastering is eliminated. The construction schedule also does not hamper much as requirement of cast- in-situ activity is minimum hence least interruption during bad weather condition .

Environmentally sustainable and saves energy:

GRC uses Industrial waste and has low embodied energy.Glass fiber reinforced concrete is an environmentally friendly product. The main ingredients of GFRC are based on naturally occurring earth oxides that are used in the manufacture of glass fiber and cement. An assessment carried out in the UK as part of a DETR and Concrete Industry Alliance ‘Partners in Technology’ project compared two concrete and GRC products that fulfill the same function. The results show that GRC has a much lower environmental impact of 60%.